| Year | Plant | Project | ||

|---|---|---|---|---|

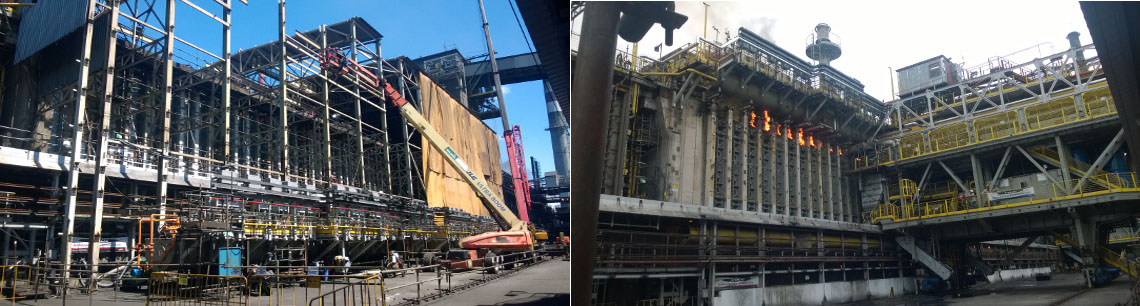

| 2018—2021 | Paul Wurth Italia S.p.A. for JSC SeverStal, Russia |

|

Construction of two blocks of stamp charged coke oven battery. Coal Handling Plant facilities. Coke Oven Plant. CDCP. Coke Handling facilities. Power facilities. Water supply and sewerage facilities. Automation. | Engineering |

| 2018—2021 | HuDe GmbH, Germany |

|

Implementation of compactification (stamping) technology for coal blend. Automation control system. | Engineering Services as Supervisor |

| 2017—2019 | Paul Wurth Italia S.p.A. for JSC SeverStal, Russia |

|

Coke Oven Battery No.11. Coke Dry Quenching. Tar decanting. Automation | Engineering |

| 2017 | SE GIPROKOKS, Ukraine |

|

Updating (correction) of detail design documentation for the facility of PJSC Severstal: COBP. Reconstruction of Coke Oven Battery No.4. Process automation system. | Engineering |

| 2011—2017 | National Mineral Development Corporation (NMDC) Limited, Coke Oven Plant, India |

|

Process Control system, Instrumentation and Automation for two Coke Oven Batteries and two CDCP | Engineering |

| 2016—2017 | SE GIPROKOKS, Ukraine |

|

PJSC Severstal. APCS. Pre-project studies. Construction of two blocks of Coke Oven Battery with coal blend stamping. BFCP. | Engineering |

| 2015—2017 | ILVA Group, ILVA Plant Taranto, Italy |

|

Coke Oven Battery No.10 reconstruction |

Engineering

Delivery of equipment |

| 2015 | SE GIPROKOKS, Ukraine |

|

Visakhapatnam Steel Plant, India. Coke Drying Cooling Plant No.5. Automation process control system. | Engineering |

| 2015 | SE GIPROKOKS, Ukraine |

|

Visakhapatnam Steel Plant, India. Coke Oven Battery No.5. Automation process control system. | Engineering |

| 2015 | SE GIPROKOKS, Ukraine |

|

PJSC Severstal. BFCP. Reconstruction of Coke Oven Battery No.8. | Engineering |

| 2014—2015 | SE GIPROKOKS, Ukraine |

|

PJSC ArcelorMittal Kryvyi Rih. Coke Oven Plant No.1. Reconstruction of Coke Oven Batteries No.5,6 complex. Process control automation. | Engineering |

| 2012—2016 | SAIL-Rourkela Steel Plant, India |

|

Rebuilding of Coke oven battery No3. Process control |

Engineering

Supervision over facility |

| 2008—2014 | Usinas Siderurgicas de Minas Gerais SA (USIMINAS), Brazil |

|

Coke Oven Batteries No3-4 Complex |

Engineering

Delivery of equipment Commissioning |

| 2014 | PJSC ArcelorMittal Kryvyi Rih, Ukraine |

|

Coke plant No1. Reconstruction of Coke Oven Batteries No5-6 | Engineering |

| 2012 | Taiyuan Iron & Steel Co., Ltd. (TISCO), China |

|

Sulphur recovery plant by monoethanolamine |

Engineering

Commissioning |

| 2011—2014 | JSC SeverStal, Russia |

|

Coke Oven Battery No7 process control |

Engineering

Commissioning |

| 2011—2014 | JSC Ural Steel, Russia |

|

Coke Oven Battery No6 process control

Coke machines process control Dry coke quenching process control |

Engineering

Delivery of equipment Commissioning |

| 2008—2012 | Iskenderun Iron & Steel Works Co. (ISDEMIR), Turkey |

|

Reconstruction of Coke Oven Battery No4

Coke machines process control |

Engineering

Delivery of equipment Commissioning |

| 2007—2008 | Pakistan Steel Co., Pakistan |

|

Coke Oven Batteries No1-2 |

Engineering

Delivery of equipment Commissioning |

| 2005—2007 | JSC ArcelorMittal Temirtau, Kazakhstan |

|

Reconstruction of Coke Oven Battery No7 |

Engineering

Delivery of equipment Commissioning |

| 2005—2007 | PJSC ArcelorMittal Kryvyi Rih, Ukraine |

|

Coke Oven Batteries No3-4 reequipment. Coke making plant |

Engineering

Delivery of equipment Commissioning |

| 2005—2007 | PJSC Alchevskkoks, Ukraine |

|

Coke Oven Battery No10-BIS complex.

Coke machines process control |

Engineering

Delivery of equipment Commissioning |

| 2004—2010 | OJSC Mechel, Russia |

|

Complex reconstruction of Coke Oven Battery No6

Reconstruction of Coke Oven Battery No2 |

Engineering

Delivery of equipment Commissioning |

| 2004—2005 | JSC Avdeevka coke making plant, Ukraine |

|

Coke machines automation system |

Engineering

Delivery of equipment Commissioning |